Tel: +86-150-1280-2327 Email: granitecomponents@163.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-12 Origin: Site

Measuring granite might seem like a daunting task, especially given its tough, dense nature. But what if we told you that getting precise measurements doesn’t have to be difficult? Whether you're crafting a beautiful granite countertop or working on a construction project, accurate measurements are key. The slightest error can lead to mismatched pieces, wasted time, and increased costs.

In this guide, we’ll take you through the process of measuring granite with confidence. From understanding the right Granite Measuring Tools to applying the best techniques, you’ll learn everything you need to know. We’ll explore tools like calipers, micrometers, and specialized granite measuring platforms—each designed to help you achieve the precision that’s crucial for every granite project.

Not only will you discover how to measure thickness, length, and angles, but we’ll also share tips on how to overcome common challenges, such as granite’s weight and temperature sensitivity. By the end of this guide, you’ll have the skills to take on any granite measurement task, ensuring your project fits perfectly, every time.

Granite is one of the hardest and most durable natural materials, widely used in countertops, flooring, monuments, and various construction projects. Its hardness and weight present unique challenges when it comes to accurate measurements. Even a slight error in measurement can have a significant impact on the final product. Whether it's cutting granite for countertops, creating slabs for construction, or installing granite tiles, precision is essential.

For instance, in countertop fabrication, even a 1mm error can cause gaps, misalignments, or issues with the overall fit of the countertop. These errors could lead to higher costs, wasted materials, and time-consuming adjustments. Using high-precision Granite Measuring Tools (such as digital calipers and Granite Measuring Platforms) helps avoid these mistakes and ensures that the granite pieces fit perfectly, maintaining both structural integrity and aesthetic quality.

The precise measurement of granite not only ensures proper fit and installation but also helps maintain the strength and durability of the material. In industries where granite is used in large-scale installations or construction, accurate measurements are crucial to ensure the project is completed on time and within budget.

In granite fabrication and installation, quality control is vital to ensure that every piece of granite meets the required standards. Accurate measurements play a key role in quality control, ensuring that the granite’s thickness, dimensions, and angles adhere to design specifications. Whether it's in a stone workshop or on a construction site, quality control’s primary goal is to avoid discrepancies, ensuring that granite surfaces perform well and meet the expected durability.

In large construction projects, granite is often used for exterior facades or flooring. If the measurements are inaccurate, the granite slabs may not fit properly, affecting the stability and safety of the building structure. Hence, Granite Measuring 00级 450x300 platforms and other professional-grade tools help ensure that all granite pieces are up to standard, preventing costly mistakes during installation.

Additionally, precise measurements allow any potential errors to be identified and corrected early in the process, minimizing the risk of rework and reducing project costs. Regular measurement checks and calibration ensure that each slab remains consistent, contributing to the overall success of the granite project.

Granite is used across a variety of industries, each requiring precise measurements for different purposes. For example, in the kitchen and bathroom industry, accurate measurements are essential for creating custom granite countertops, sink fittings, and edge designs. A small error in measurement can lead to misaligned surfaces or gaps between slabs, affecting both the aesthetic and functionality of the final product.

Granite also plays a major role in construction, particularly in flooring and wall applications. For these projects, precision is crucial to ensure that the granite tiles or slabs fit properly within the designated space, creating a seamless and uniform appearance. Similarly, granite is often used in monumental and memorial applications, where the artistic precision of engraved or cut designs is essential.

In all these fields, the importance of accurate granite measurements cannot be overstated. Whether it’s for countertops, flooring, or monuments, using the right Granite Measuring Tools, like Black Granite 1m Platform, is essential to ensure that the material meets its intended use and design specifications.

Measuring granite comes with its unique set of challenges. First, granite surfaces may not be perfectly smooth, and irregularities can interfere with the precision of measurements. These surface imperfections can make it difficult for measuring tools to make full contact with the surface, potentially leading to errors in the measurement. Additionally, the hardness and weight of granite can make manual measurements difficult, especially when handling large slabs.

Another common issue is temperature fluctuations. Although granite expands and contracts minimally with temperature changes, even slight shifts can affect its measurements. These temperature-induced changes can be especially important when working with large pieces of granite, which may expand or contract across different parts of the slab. For this reason, measurements should always be taken in a controlled environment to minimize the effects of temperature variation.

To overcome these challenges, using a Granite Measuring 300x200 platform ensures that the surface is stable and level, reducing the risk of measurement inaccuracies. Professional-grade tools help mitigate errors caused by irregularities in the granite’s surface and ensure that precise measurements are taken across the entire piece, regardless of its size or shape.

For measuring the thickness and fine details of granite, calipers and micrometers are essential tools. These instruments provide precise measurements down to a fraction of a millimeter. Calipers, particularly digital ones, can help you measure the thickness of slabs, while micrometers offer the highest level of precision for smaller measurements.

Tool | Use Case | Precision Level |

Calipers | Measuring the thickness of granite slabs | High precision for thickness |

Micrometers | Measuring small variations in granite edges | Extreme precision (0.001mm) |

Both tools are necessary for ensuring the granite pieces meet exact specifications. They are especially useful in custom-cutting applications where precision is paramount.

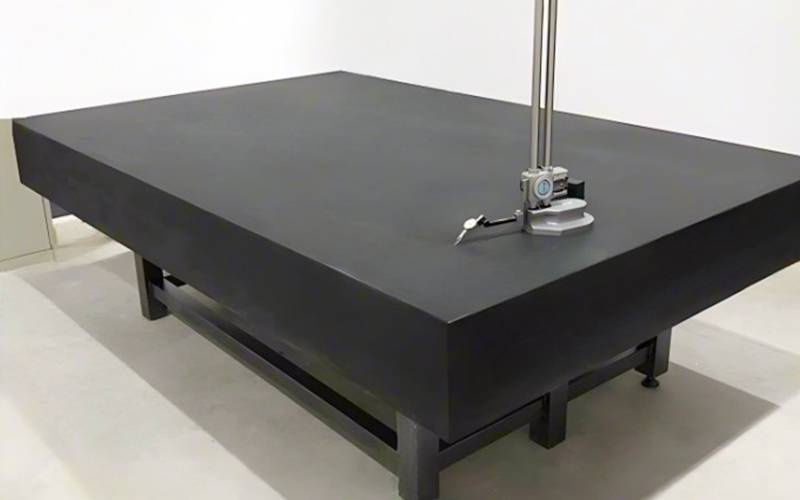

A Granite Measuring Platform is a must-have for achieving precise measurements, especially for larger granite pieces. These platforms provide a flat, stable surface on which to place the granite slab during measurement.

Using a Granite 600x400 platform or similar models helps eliminate surface imperfections that could affect measurements. Granite is heavy and sometimes uneven, and using the right platform ensures accurate, reliable measurements by stabilizing the granite during the measuring process.

Platform Model | Size (mm) | Features | Ideal Use |

Granite Measuring 300x200 | 300x200 | Compact, highly stable for smaller projects | Small to medium granite slabs |

Granite 0级 600x400 | 600x400 | Large, highly precise for large slabs | Large slab measurement |

Granite Metrology 500x500 | 500x500 | Industrial-grade, high precision | Industrial applications |

Laser measuring tools are becoming increasingly popular for measuring large granite slabs. These tools use laser beams to measure distances and angles, providing high accuracy without needing direct contact with the surface. This is particularly useful for large slabs of granite, where traditional tools may not be practical.

Laser measuring tools allow for quick and accurate measurements across the entire surface of a granite slab. They are especially beneficial when measuring the length, width, and height of granite used for countertops or large installations.

When it comes to granite edges, the measurement of angles is just as important as the thickness and length. Protractors and angle finders help ensure that granite edges are cut with perfect angles. These tools are vital for applications such as installing granite countertops, where edge angles affect the final fit.

Using tools like digital protractors helps minimize errors in the angle measurements, ensuring that each granite piece fits precisely with the next.

Before taking any measurements, ensure that the granite surface is clean, flat, and level. Dust, debris, and even minor irregularities can affect the accuracy of your measurements. Here are the steps to prepare granite for measurement:

● Clean the surface: Use a soft cloth or air blower to remove any dirt or particles.

● Level the granite: If the slab is not already level, place it on a Granite Flat 300mm Square to ensure that it sits flat for accurate measurement.

For general measurements, start with a caliper or micrometer to measure the thickness of the granite slab. Then, use a measuring tape or laser tool to measure the length and width. These tools are vital for ensuring the granite fits in the desired space, whether for countertops or tiles.

The thickness is crucial for structural integrity, while the length and width must be measured to match the intended installation area.

Granite edges and angles are essential when cutting granite slabs. Using a digital protractor or angle finder will help you accurately measure angles along the edges. These measurements are crucial for ensuring that granite pieces fit together correctly when assembled, especially for countertop or decorative work.

When preparing granite for cutting, it is important to measure twice to avoid mistakes. Use a granite measuring platform to ensure the slab remains level while you take multiple measurements. For projects that require precision cutting, tools like micrometers can help ensure the granite is cut to the exact specifications.

Measuring granite comes with its challenges. Common errors include misalignment of the granite slab or inaccurate readings from faulty tools. Always double-check measurements and ensure that tools are properly calibrated. The use of a Grade 00 Granite Base can help provide a stable, error-free surface.

Granite slabs can be heavy and difficult to move. Always use proper lifting equipment to handle the slabs safely. Wear protective gloves and equipment to avoid injury, and ensure the slab is securely placed on a stable surface like a Black Granite 1m Platform.

To maintain accuracy, regularly calibrate your measuring tools. Calipers and micrometers should be recalibrated every so often to ensure that they provide consistent results. Proper maintenance of tools will help maintain their longevity and accuracy.

High-quality granite measuring tools can be an investment, but they are necessary for precise work. Digital calipers, micrometers, and Granite Measuring Tools can be more expensive than their manual counterparts, but the accuracy they provide is worth the cost, especially for large-scale or custom granite projects.

Not all granite measuring tools are the same. Depending on the size of the granite and the level of precision required, different tools may be more suitable. For example, smaller pieces of granite may only require basic calipers, while larger slabs benefit from the use of a Granite Measuring 00级 450x300 platform or laser measuring tools.

Taking accurate measurements of granite is essential for ensuring quality and precision in any granite-based project. By using the right Granite Measuring Tools, such as calipers, micrometers, and measuring platforms, you can ensure that your granite pieces fit perfectly and function as intended. Whether working with large slabs or intricate edges, the right tools and techniques will allow you to achieve the level of precision needed for success. With proper preparation, the right equipment, and attention to detail, measuring granite becomes a straightforward and reliable process.

Accurate measurements of granite are crucial for any successful project. The use of proper Granite Measuring Tools, such as calipers, micrometers, and Granite Measuring Platforms, ensures precise results. By following the right techniques, you can avoid costly errors and ensure your granite pieces fit perfectly. SYIN Automation Technology Co., Ltd offers high-quality measuring solutions, including precision Granite Measuring Platforms, which help improve the accuracy and reliability of granite measurements in various industries. Their tools are designed to streamline your workflow, ensuring long-term efficiency and accuracy.

A: The best Granite Measuring Tools include digital calipers, micrometers, and a Granite Measuring Platform. A Granite Metrology 500x500 platform provides stability for large granite pieces, ensuring accurate measurements.

A: A Granite Measuring Platform ensures a stable, flat surface for precise measurements. Using a Black Granite 1m Platform helps prevent inaccuracies caused by surface irregularities during the measurement process.

A: To measure granite thickness, use a Precision Granite Measure Plate along with a micrometer or calipers. Ensure the slab is placed on a stable Granite Flat 300mm Square platform for maximum accuracy.

A: Use a digital protractor or angle finder to measure granite edges. A Granite Inspection 400x300 platform can help ensure the granite is level, minimizing measurement errors when checking angles.